Examples of robotics in the beverage industry are on the rise. Universal Robots’ human-based cobots can perform repetitive tasks such as making tea, cleaning cups, labeling drinks and serving drinks to customers, while employees can move on to more value-added work.

Repetitive pick-and-place applications in the beverage industry can be performed without interrupting production with Universal Robots’ high-precision cobots. With their small footprint, low energy consumption, and ±360-degree movement capability on all axes, cobots provide significant advantages in packaging and palletizing applications, which are used intensively in the beverage industry.

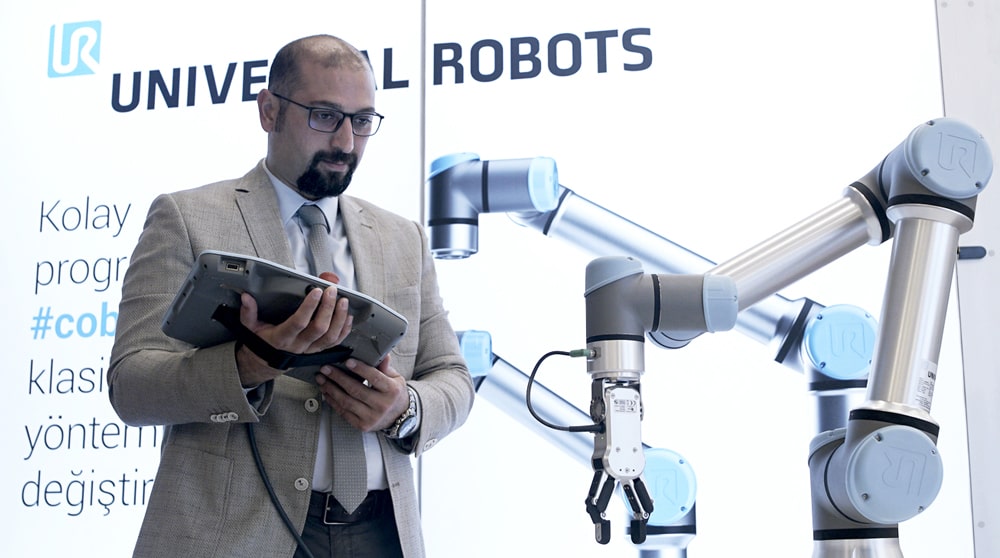

“Successful automation without creating extra costs”

Mentioning the points to be considered in the use of robots in the beverage sector, Universal Robots Turkey and MEA Country Manager Kandan Özgür Gök said, “The most common robotic applications in the beverage sector are packaging, palletizing, and pick-and-drop. In these applications, it is necessary to pay attention to the correct position in which we will pick up and drop the part. With the UR+ that we offer as Universal Robots, a quick integration can be made with a gripper and camera solution to be selected for these applications. Universal Robots offers the ‘conveyor tracking function’ as a standard internal feature in all robot models and series. Parts can be picked up both while standing in a fixed position and while moving on the conveyor. Thanks to the internal conveyor tracking function, automation is successfully implemented without creating any extra costs. In the sector, internal communication structures are offered as an option and can be purchased for a fee, just like the conveyor tracking function. Therefore, additional costs arise when it is necessary to communicate with a different machine via a different communication protocol. In Universal Robots, different communication protocols are offered free of charge, just like the conveyor tracking function.”

“It is necessary to pay attention to the strength balance in transportation applications”

Continuing with other points to be considered, Gök said, “The beverage sector is entering into transportation applications. It is important to pay attention to the following in transportation applications; for example, when palletizing, there are different floors on the pallet, let’s say you put 10 products in each row 7 floors on top of each other. You need to make a strength balance here so that the upper floors do not tip over while being transported. Therefore, different alignments need to be made on the first floor and the second floor. After the products on the different floors are placed on the pallet, it is necessary to prevent the products from shaking and tipping over on the pallet while moving from one point to another with a forklift or other conveyor transport equipment. When you offer different alignment options on each floor in different combinations, it is possible to prevent tipping. In addition, it is very important to be able to pick up the part from the right place. In this regard, mechanical guidance and referencing should be used or the position information of the part should be sent to the cobot by the camera. Finally, for the pickup of the parts moving on the conveyor, the conveyor synchronization and the speed information of the synchronization need to be done very well by the system integrator. “As Universal Robots, we provide solutions for all the situations that I have listed,” he said.

“We are increasing the ability to use cobots with the Application Wizard” Gök said, “Our newly developed Application Wizard offers a step-by-step process for selecting the appropriate end equipment and the right robot required for the application through online configuration, reviewing the advantages and disadvantages of different configuration options, and learning the skills required for a complete solution. Thanks to our advantages of Universal Robots+, Universal Robots Academy and our latest innovation Application Wizard, we are increasing the ability to use robots in all kinds of applications. We allow everyone to quickly configure and implement a successful robot application,” he concluded.